-

How M&B’s Hangers are Made

Wire garment hangers begin as huge coils of wire rod that weigh 3,000 to 5,000 pounds apiece. The steel rod is almost a quarter inch in diameter. We clean it (using mechanical processes, not harmful chemicals) and stretch it like taffy until it thins down to the gauge that we need. For our standard drycleaning hangers, that’s less than half its original diameter.

We straighten the resulting wire and cut it to the appropriate length for each type of hanger.

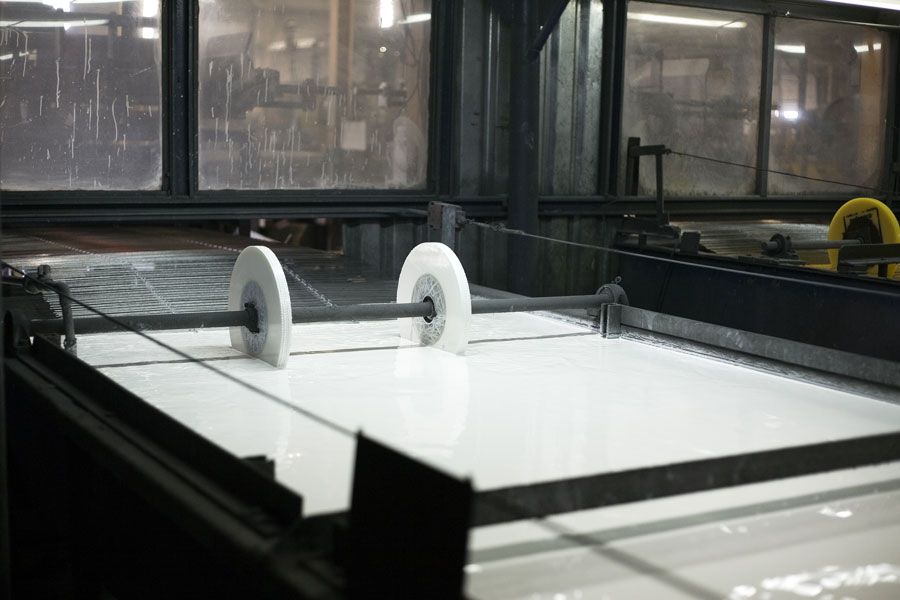

Next, we coat each length of wire with an environmentally safe electrodeposition paint. Specially made machines then form the wire into hangers.

We use similar processes for strut hangers (with cardboard tubes on the bottom) and cape hangers (covered in paper). For struts, we manufacture our own tubes, then mechanically assemble them to preformed strut wire.

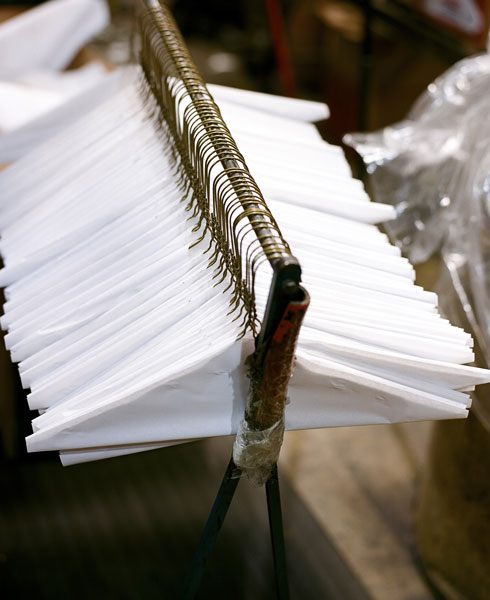

For capes, we unroll the paper from large rolls, print it with the desired design, cut it, and mechanically assemble it to the hanger, all in one process.

From there, all hangers get packaged, palletized, and wrapped, leaving them ready for shipping.